Auto-Focus Power Advantages

- No Sacrificed Profiling Boards

- Quick Production Start Up

- New Recipe Suggestion Without Running a Profile

- Reduced Oven Electricity Use

- Fast New Product Introduction

- 24 Hour Customer Service

- Auto-Focus Power datasheet

- Auto-Focus Power A4 size datasheet

Technical Support 24 Hours Every Day Everywhere, Risk Free Guarantee

All KIC products are designed to give maximum value and fast payback by streamlining your thermal process. Investment in a KIC product is a step toward total process control and quality management. All KIC products come with a no questions asked, 30 day money back guarantee.

For more information on any of our products or service please visit us on the Web at: www.kicthermal.com or www.KIC.cn

Service Available

- Technical Support

- Installation and Setup

- Application Support

- Hardware Support

- Guaranteed Warranty

Conveniently view and share profiles on mobile devices

Software Description

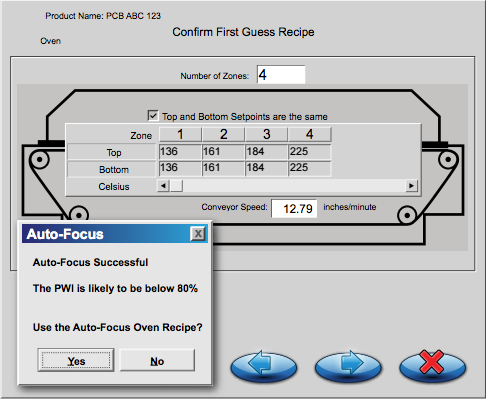

Auto-Focus Power™ is a ‘recipe search engine’ with an intelligent database Every manual profile will populate the database. The correlations between the oven properties, thermal transfer rate, PCB characteristics and varying process windows enable very accurate oven setup recommendations In short time, the database becomes intelligent enough that a recommendation for best oven setup for any new PCB will be generated without the need to run a new profile Only input of the new PCB’s length, width and weight is required for the software to recommend the best oven recipeInitial Oven Set Up

A new product requires the selection of an appropriate reflow oven recipe. Manual profiling will help identify the correct setup, but to select the initial recipe requires an educated guess A poorly selected initial recipe runs the risk of: Damaging the product Requiring numerous profile runs before identifying the correct recipe The Auto-Focus Power™ recommends the initial setup without running a profile and without the need for the technician’s educated guess – within seconds.Optimization Criteria

Lowest energy use The center of the process window Maximum throughput Fastest oven changeover (or a combination of these)Reduced Electricity Consumption

Case studies indicate an instant 15% drop in electricity use in reflow ovens. Where do the savings come from? Few reflow ovens are set up with consideration for electricity consumption, so they tend to run hot and fast KIC’s Auto-Focus Power takes the slack out of the process by optimizing both throughput and heat/energyEase of Use – Ease of Results

Process insight and expertise built into the software Define the process window and minimum conveyor speed – delegate the rest Oven set up tasks may be handled by less experienced personnel – quickly Less production downtimeVersatile and Low Cost

Auto-Focus Power™ works with KIC profilers. Works on virtually any reflow oven on the market – old or new The ROI tends to be exceptionally high due to the low investment cost combined with big cost savingsExceptional Value

The KICstart²™ thermal profiler utilizes core technologies developed by KIC, the world’s premier thermal profiling company, and is supported by KIC’s worldwide organization. Packaging these innovative technologies into a low-cost system, the KICstart² is an ideal cost effective thermal profiler.Ease of Use

The KICstart² profiler has everything you need to quickly acquire an accurate profile, without complicated features that can slow you down. For applications where all you want is your product’s thermal profile, immediately with no fuss, the KICstart² is for you. The patented design concept automatically identifies the location of each oven heating zone, so no or few measurements are required. This design automatically corrects for different TC locations on the part, aligning them for improved profile graph viewing. Production down time is reduced when using the Manual Prediction software which enables the process engineer an instant “trial and error” capability when searching for more suitable oven recipes. The profiling data is automatically transferred to a PC when plugging in the USB cable. With its easy to use and intuitive software, new personnel can be trained in record time.Instant Process Analysis

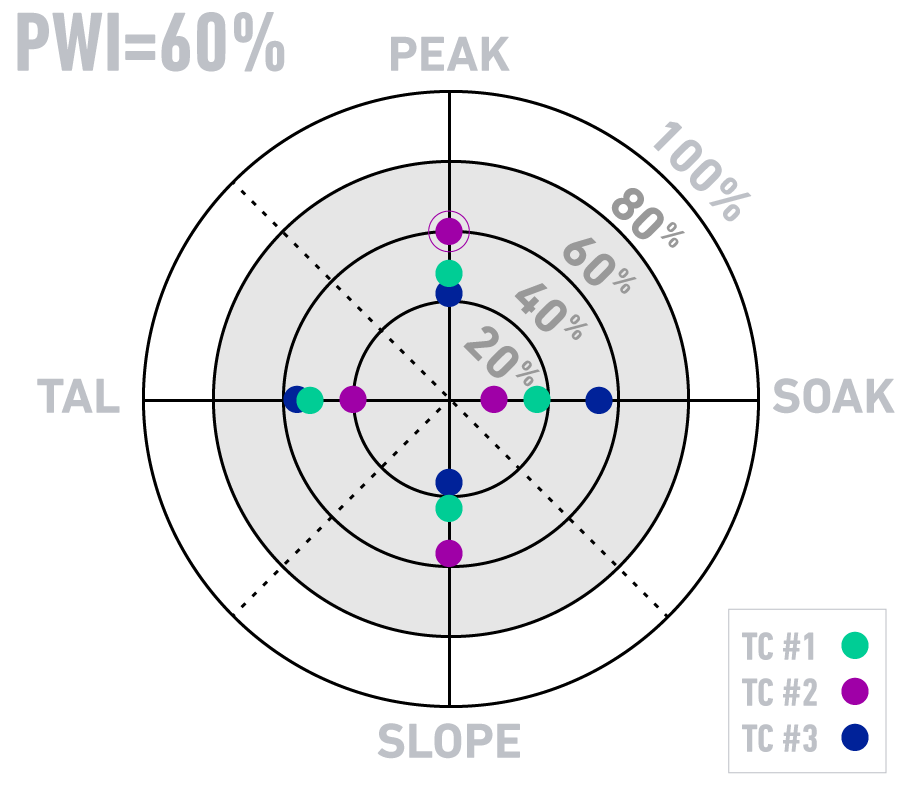

Once your profile has completed, the KICstart² automatically analyzes your process using the Process Window Index™ (PWI™). The PWI is a single number that measures how well your profile fits within your product’s thermal process window (See the Process Window Index data sheet for details). The PWI provides an instant and objective conclusion whether your product profile is in spec, eliminating guesswork and opinion from process analysis. This helps you ensure that all your products on all your lines are manufactured with measurable, consistent quality.Reliable and Robust

The superior accuracy and reliability of the KICstart² is nothing less than you would expect from KIC’s award winning product line. The KICstart² is a six thermocouple datalogger unit that utilizes solid state technology designed to withstand the daily or weekly thermal cycles for years to come, for both lead- free and leaded assemblies.

The KIC Auto-Focus and KIC Auto-Focus Power is simple, fast and easy to use, requiring minimal input or technical experience. Once the necessary criteria are provided, Auto-Focus goes to work and in seconds you are presented a suggested initial oven set up. The recipe is ranked using the Process Window Index (PWI), so you immediately know where it falls within your process specifications.

Auto-Focus Power searches for the oven recipe with the lowest electricity use while positioning the profile in spec.

KIC Auto-Focus includes the KIC® Navigator™ software option. KIC Auto-Focus Power includes the KIC® Navigator™ Power software option. Auto-Focus and Auto-Focus Power expand the capability and potential of the KIC software by automatically optimizing your process set up.

Note: The KIC software may interface directly with some oven controllers, eliminating the need for manual setpoint data entry. Please consult your oven supplier for availability. The KIC software is dongle protected.

The Process Window Index

Profiling Reduced to a Single Number

The PWI measures the profile’s fit to the process window in a mathematical and objective manner by using a single number. This aids in optimizing the process by comparing and ranking alternative profiles in terms of their fit to the available process window. The lower the PWI, the more efficient and stable the process! (See the PWI data sheet for a detailed explanation)