Thermal Process Set Up Tool for Lower Electricity Use

- Reduce energy costs

- Enable deep in spec profile

- Maximize product throughput

- 24 Hour customer support

- Navigator Power datasheet

- Navigator Power A4 size datasheet

Case Studies

Several case studies reveal a typical electricity saving of approximately 15%

Risk Free Guarantee All KIC products are designed to give maximum value and fast payback by streamlining your thermal process. Investment in a KIC product is a step toward total process control and quality management. All KIC products come with a no questions asked, 30-day money back guarantee.

Reflow Oven Set Up for Lower Electricity Use – Improve Production Quality

Technology for Lower Electricity Use

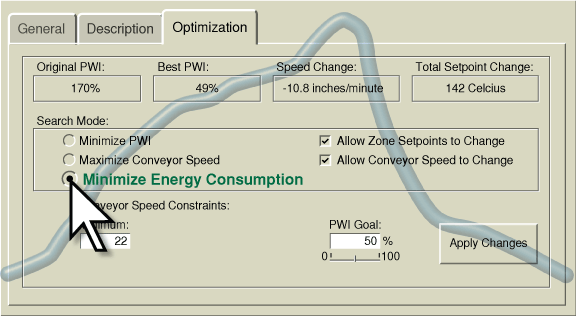

Navigator Power selects the best oven recipe based on user selected criteria:- Minimum electricity use

- Deep in spec profile

- Maximized throughput

- Minimized oven changeover time

- Most reflow ovens are set up without considerations of electricity use

- Reflow ovens tend to run too hot and too fast

- Software simulation identifies the oven recipe that will yield the lowest electricity use based on the above criteria

- Instantly

What is required to achieve the electricity savings?

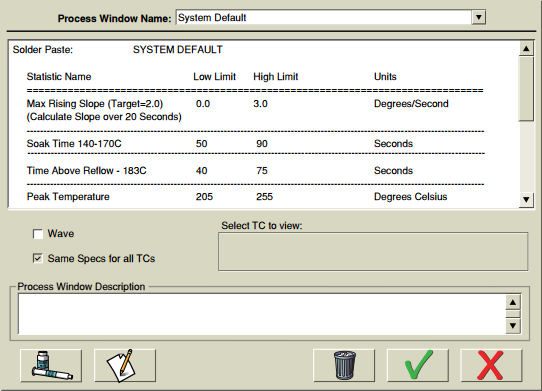

- Knowledge of the appropriate process window

- One initial profile run with TCs on the product

- Knowledge of minimum allowable reflow oven conveyor speed

- KIC Navigator Power and a KIC profiler

- Nothing else

Ease of Use Software

- Most profiling tasks are automated and run invisibly in the background

- The user interface enables the responsible engineer to select the higher level criteria such as process window and minimum conveyor speed

- Everything else can be delegated

- The ease of use software means faster oven set up and lower production downtime

KIC Navigator Power

Edit the Process Window Screenshot

KIC Navigator Power™ expands the capability and potential of the KIC software by automatically optimizing your process set up.

KIC Navigator Power™ is a stand-alone software option and is also included with the KIC Auto-Focus Power™ software option.

Note: The KIC software may interface directly with some oven controllers, eliminating the need for manual setpoint data entry. Please consult your oven supplier for availability. The KIC software is dongle protected.

Computer Configuration

Minimum System Requirements

- Dual Core / 1 GHz Processor PC with 2 GB RAM

- 2 GB available storage

- Video 1024 x 768 resolution / 16-bit

- 1 available USB port (for software key)

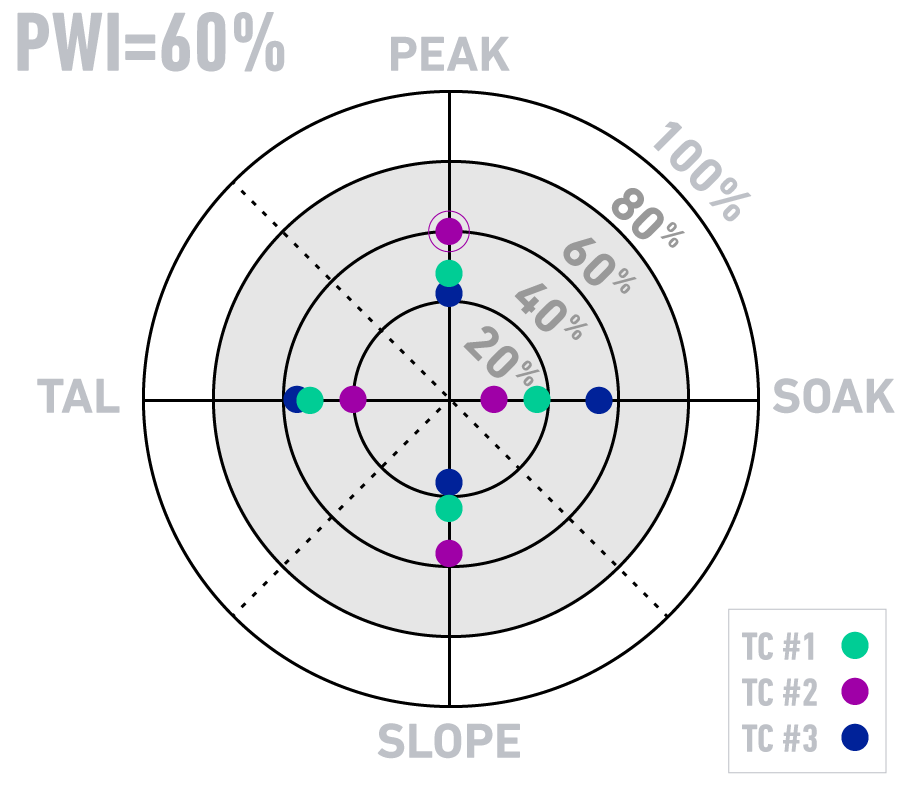

The Process Window Index

Profiling Reduced to a Single Number

The PWI measures the profile’s fit to the process window in a mathematical and objective manner by using a single number. This aids in optimizing the process by comparing and ranking alternative profiles in terms of their fit to the available process window. The lower the PWI, the more efficient and stable the process! (See the PWI data sheet for a detailed explanation)