K² Advantages

- Robust Hardware

- Ease of Use

- Oven Setup Software

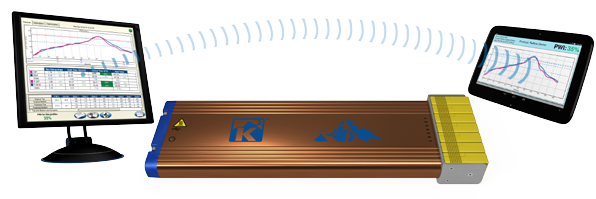

- Viewing on Mobile Devices

- 24 Hour World Class Customer Support

- KIC Profiler K² datasheet

- KIC Profiler K² A4 size datasheet

Technical Support 24 Hours Every Day Everywhere, Risk Free Guarantee

All KIC products are designed to give maximum value and fast payback by streamlining your thermal process. Investment in a KIC product is a step toward total process control and quality management. All KIC products come with a no questions asked, 30 day money back guarantee.

For more information on any of our products or service please visit us on the Web at: www.kicthermal.com or www.KIC.cn

For more information on any of our products or service please visit us on the Web at: www.kicthermal.com or www.KIC.cn

Service Available

- Technical Support

- Installation and Setup

- Application Support

- Hardware Support

- Guaranteed Warranty

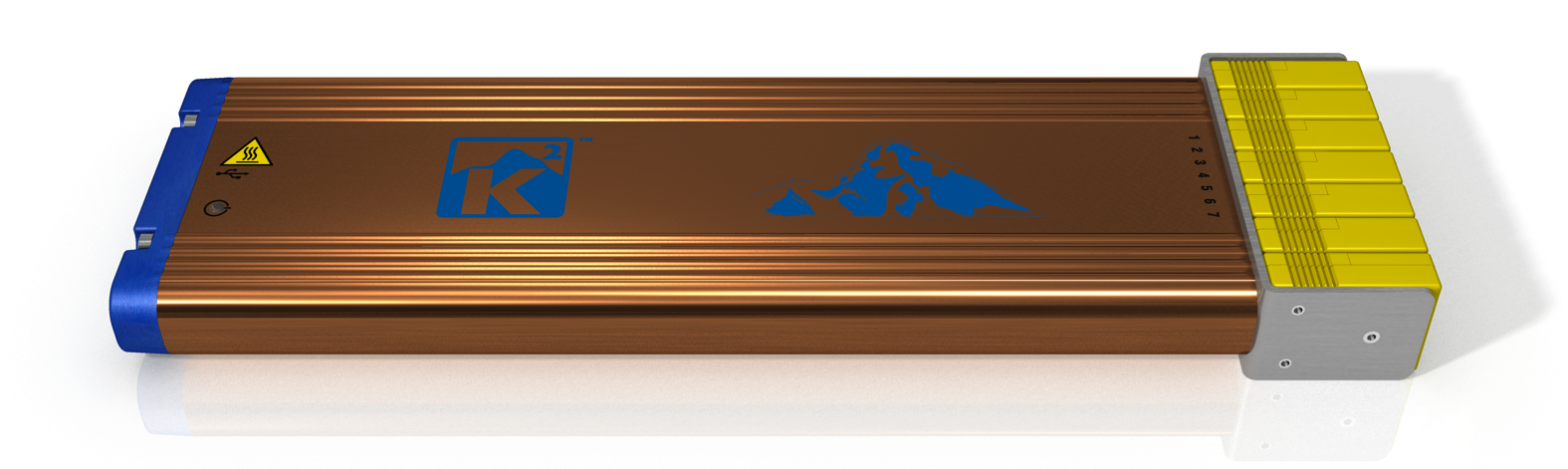

K² – The New KIC Profile Setter

Conveniently view and share profiles on mobile devices

New Generation Mid-Range Profile Setter

- New generation profile setter replaces the last of KIC’s older technology profilers

- Competitively priced for the mid-range market

Compact and Robust Hardware

- The K² will fit through the tight heated chambers often found in lead-free production

- 7 TC unit dimensions:

- 206 x 60 x 17 (mm)

- Shield: 302 x 75 x 23 (mm)

- 9 TC unit dimensions

- 206 x 75 x 17 (mm)

- Shield: 312 x 90 x 23 (mm)

- Durable hardware designed to withstand rough production environments

Fail-Safe Operation

- Automatic start when temperatures are below a specified ‘start’ trigger, protecting the K² and assuring consistent starting points and repeatable profiles

- Hardware designed for accurate measurements

- Engineer sets quality and productivity related parameters:

- PWI level

- Minimum/maximum allowable conveyor speed

- Maximum peak temperature,etc.

- For use by operators, technicians and engineers

Oven Setup Software

- KIC’s optimization software does a complete search for all possible combinations of oven zone temperatures and conveyor speeds. It selects the very best oven setup for each new product within seconds

- User selectable setup criteria focuses on positioning the profile towards:

- the center of the process window

- maximum conveyor speed

- minimum oven electricity usage

Instant and Objective Profile Analysis

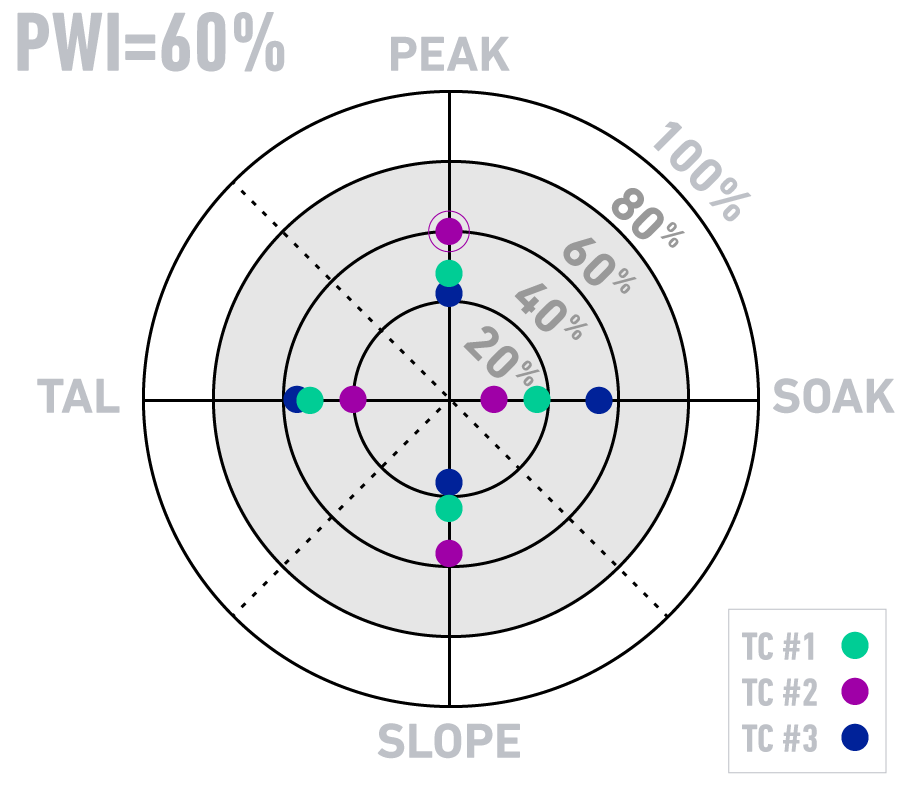

- KIC’s famous Process Window Index (PWI) explains how the profile fits the established process window, with a single number:

- PWI above 100 = profile out of spec

- PWI at 100 = profile right on the spec limit

- PWI below 100 = profile in spec

- PWI at 0 = the exact center of the process window

- Immediate profile analysis

- Objective and personnel-independent profile analysis

- Outlying profile data made visible

Accessing the K² Profile Data on the PC or Mobile Device

- The profile data can be displayed in two ways:

- On the oven PC or profiling PC

- On an Authorized Android mobile device

- Convenient sharing function for selected profile data

| Accuracy | ± 0.5°C |

| Resolution | 0.1°C |

| Internal Operating Temp: | 0°C to 85°C |

| Sample Rate: | 0.1 to 10 readings/sec |

| Data Points: | 224,640 |

| PC Connection: | USB 2.0 (Std-A/Mini-B) |

| Power Requirements: | (3) AAA batteries |

| Thermocouple Compatibility | |

| 7, 9, 12 Channel Unit | Type K, Standard |

| Temperature Range: | -150°C to 1050°C |

| Dimensions (L x W x H mm): | |

| 7 Channel Unit: | 202.0 x 60.0 x 17.0 |

| 9 Channel Unit: | 202.0 x 75.0 x 17.0 |

| 12 Channel Unit: | 208.0 x 98.0 x 17.0 |

| Thermal Shield: | See Temperature |

| Tolerance Table below for specifications. | |

The Process Window Index

Profiling Reduced to a Single Number

The PWI measures the profile’s fit to the process window in a mathematical and objective manner by using a single number. This aids in optimizing the process by comparing and ranking alternative profiles in terms of their fit to the available process window. The lower the PWI, the more efficient and stable the process! (See the PWI data sheet for a detailed explanation)| Shield | DIMENSIONS (mm) (Length x Width x Height) |

150C | 200C | 250C | 300C | 350C | 400C |

|---|---|---|---|---|---|---|---|

| Cool Touch Stainless Steel Shield, 7 CH | 302 x 75 x 23 | 17.5 | 12.0 | 9.0 | 7.7 | 6.5 | |

| Cool Touch Stainless Steel Shield, 9 CH | 312 x 90 x 23 | 18.1 | 13.1 | 10.1 | 8.4 | 6.7 | |

| HT Shield 400 | 298 x 106 x 29 | 24.9 | 17.6 | 14.0 | 11.5 | 10.1 | 9.2 |

K² Kit Contents

- Profile Setter

- Thermal Shield

- Software CD

- Software Protection Dongle

- USB Cable (A Male/Mini-B)

- AAA Batteries (6)

- Scissors

- Thermocouples

- Carrying Case

- Electronic User Manual

- Electronic Hardware Guide

- Gloves

- Getting Started Guide

- Calibration Certificate

Computer Configuration

Minimum System Requirements- Dual Core / 1 GHz Processor PC with 2 GB RAM

- 2 GB available storage

- Video 1024 x 768 resolution / 16-bit

- 1 available USB port (for data download)

- 1 available USB port (for software key)